Technology Center Transformation: VU reveals three new state-of-the art labs

Technology Center Transformation: VU reveals three new state-of-the art labs

October 21, 2022

VINCENNES, Ind. – A new Center for Applied Robotics and Automation, Additive Manufacturing and Reverse Engineering Center, and HURCO Advanced CNC Machining Technology Center embody Vincennes University’s commitment to innovation, state-of-the-art technologies, extraordinary educational experiences, and powerful industry partnerships.

The first-class centers were unveiled during an open house in the College of Technology Center on the Vincennes Campus this month.

VU is a leader in providing Indiana and the nation’s workforce with the skills needed in today’s technology-driven advanced manufacturing industries.

VU is a leader in providing Indiana and the nation’s workforce with the skills needed in today’s technology-driven advanced manufacturing industries.

VU is preparing students for the jobs of today and tomorrow. The three centers represent a $4.8 million investment that ensures VU is producing career-ready graduates.

According to VU President Dr. Chuck Johnson, “Vincennes University is delighted to have three new centers that will create more opportunities for students and will help support the needs Hoosier employers have for skilled talent. Vincennes University has a deep commitment to student achievement, and the three centers will enhance the educational experiences of many students that will have a significant positive impact on VU, the State of Indiana, and across the nation for decades to come.”

U.S. Congressman Larry Bucshon described the new spaces as outstanding. While touring the centers, he pointed out that VU is always ahead of curve.

“The equipment is the most up-to-date technology,” Bucshon said. “This is the type of training that we need for the workforce of today. We need high-tech workers who have skills, and this is an outstanding university for that.”

The centers are yet another example of how VU is moving the State of Indiana forward in a bold way, thereby positively impacting the economy and communities.

"We have a lot of job openings out there,” Bucshon said. “We have companies that are literally begging to find qualified employees, so the more of those people who we can get trained and into the workforce, it benefits everybody.”

The cutting-edge laboratories guarantee students access to the latest technology and facilities which are relevant to industry needs, foster new skills, and ready the future workforce.

“Hands-on learning is really important in developing the skills and knowledge needed to keep up in industry today and in the future,” VU Provost Dr. Laura Treanor said. “The facilities and equipment in the new centers represent a very nice new space that provides a great learning environment for our students, but it is VU’s high-quality faculty and staff, who are dedicated to student learning that make the biggest impact on our students’ success. They are the ones who make the programs so highly successful and so highly valued by our employers.”

VU continues to make key investments that support the efforts of the University’s industry partners and employers throughout Indiana and beyond. The centers further the University’s initiatives to provide training and education that support the next generation of advanced manufacturing technology and develop a skilled talent pipeline for industry partners.

“The lab spaces are in place because of the needs of our industry partners,” VU College of Technology Dean Ty Freed said. “Indiana is a huge manufacturing state. When you talk about all 50 states, Indiana is really a power player in manufacturing.”

Before touring the new centers, attendees heard from the featured speakers at the open house, including Johnson, Treanor, Freed, Board of Trustees Chairman John Stachura, Director of Architectural Services and Facilities Andrew Young, and Albert Chen, Telamon Corporation Founder and Executive Chairman of the Board. Then it was time to explore the modern and inviting labs.

Check out our new centers.

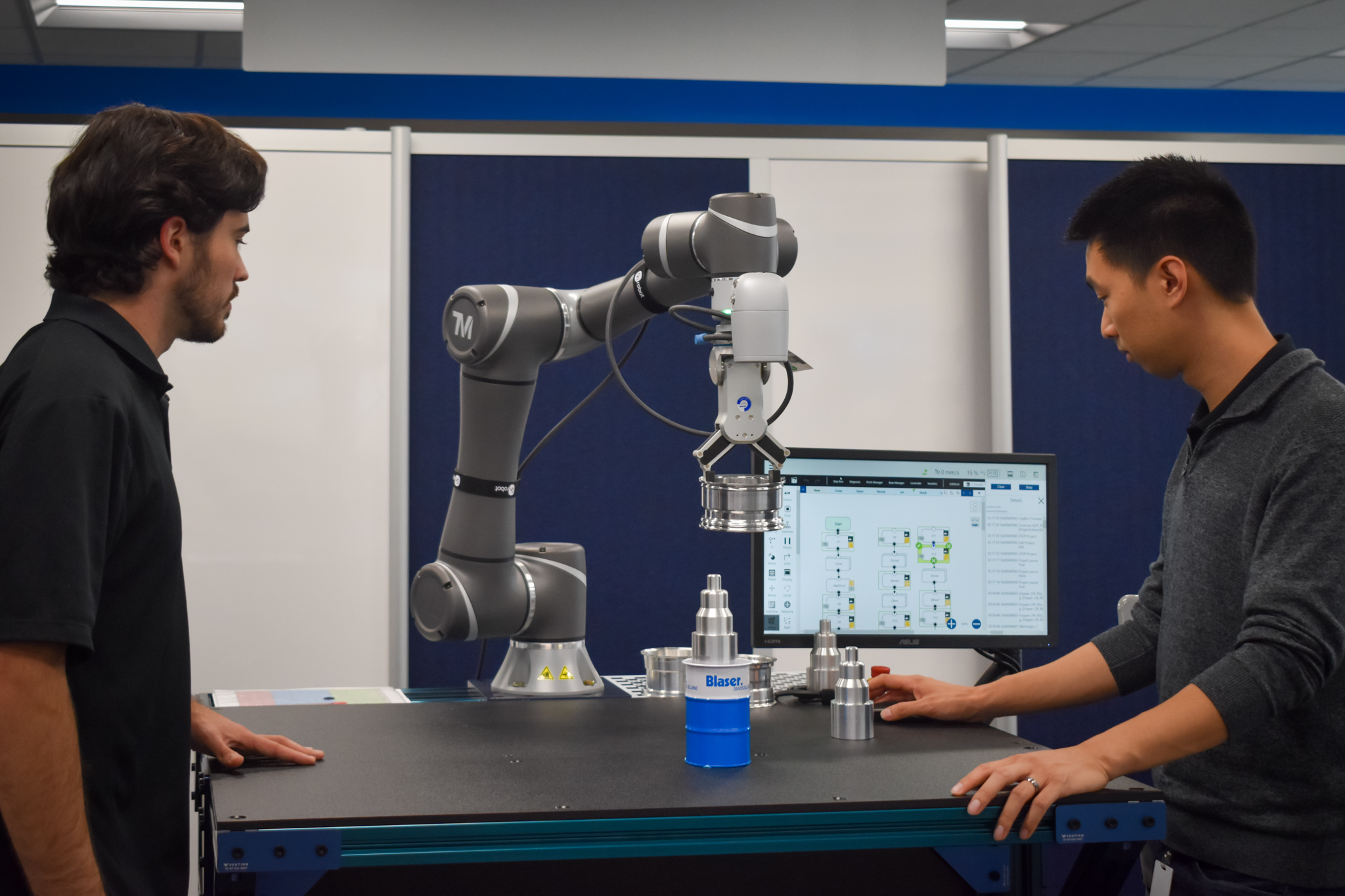

Center for Applied Robotics and Automation (CARA)

VU is a national leader in the emerging technology of collaborative robots or cobots. Collaborative robots are a form of robotic automation built to work safely alongside human workers in a shared, collaborative workspace in various industries such as manufacturing, medical, and aviation. In most applications, a collaborative robot is responsible for repetitive, menial tasks, while a human worker completes more complex and thought-intensive tasks. The creation of the CARA was made possible with support from an $8 million grant from Lilly Endowment Inc. Through a partnership with Carmel-based Telamon Robotics, the 4,050-square foot CARA is home to 12 cobots with end-of-arm-tooling or smart grippers from OnRobot and custom stations by Vention. As the market evolves, the mission of the CARA, in collaboration with other related programs at VU, is to prepare students and upskill Indiana’s workforce to support the existing and future needs of programming, coding, maintaining, creating systems, developing, implementing and managing collaborative robotics solutions in various industries across Indiana and nationally. The training lab will also allow VU to provide employers with demonstrations, workshops, and access to cobot technologies, applications, and models. The CARA is VU’s fourth cobot lab. The University currently has 10 cobots at its Gene Haas Training and Education Center in Lebanon, Indiana, and another 10 cobots at the VU Jasper Campus. VU also plans to deploy 10 cobots at partner high schools.

Hurco Advanced CNC Machining Technology Center

The 2,330-square-foot facility houses VU’s Hurco training center and features the latest CNC machine tool technologies. The lab underwent a floor-to-ceiling renovation over the summer. The center features 17 new CNC mills and lathes. Each machine is networked and has a dedicated work station that includes a computer with the newest version of Mastercam software, which like the Indianapolis-based Hurco is an industry partner. There has also been a change when it comes to the coolant used. A top-of-line synthetic-based liquid tool coolant provided by industry partner, Blaser Swisslube, is used in the lab. There’s also new lighting and acoustics. A new addition is coming soon when a CNC-controlled laser marking and cutting system, which typically costs $65,000, will be added to the center.

Additive Manufacturing and Reverse Engineering Center

Additive manufacturing or 3D printing is the construction of a three-dimensional object from a model. VU’s 2,930-square-foot lab houses a large variety of 3D printers that can print 3D objects and make them out of everything from powder to filament to resin to metal. The space also houses digitizers and scanners that create cloud point data and scan existing geometry to input into computer-aided design (CAD) software.

Explore VU’s College of Technology and its bachelor’s, associate, and certificate programs.

###